Features that deliver

Watch our explanatory Transporter films here

Watch the Carrier Basket Transporter in action

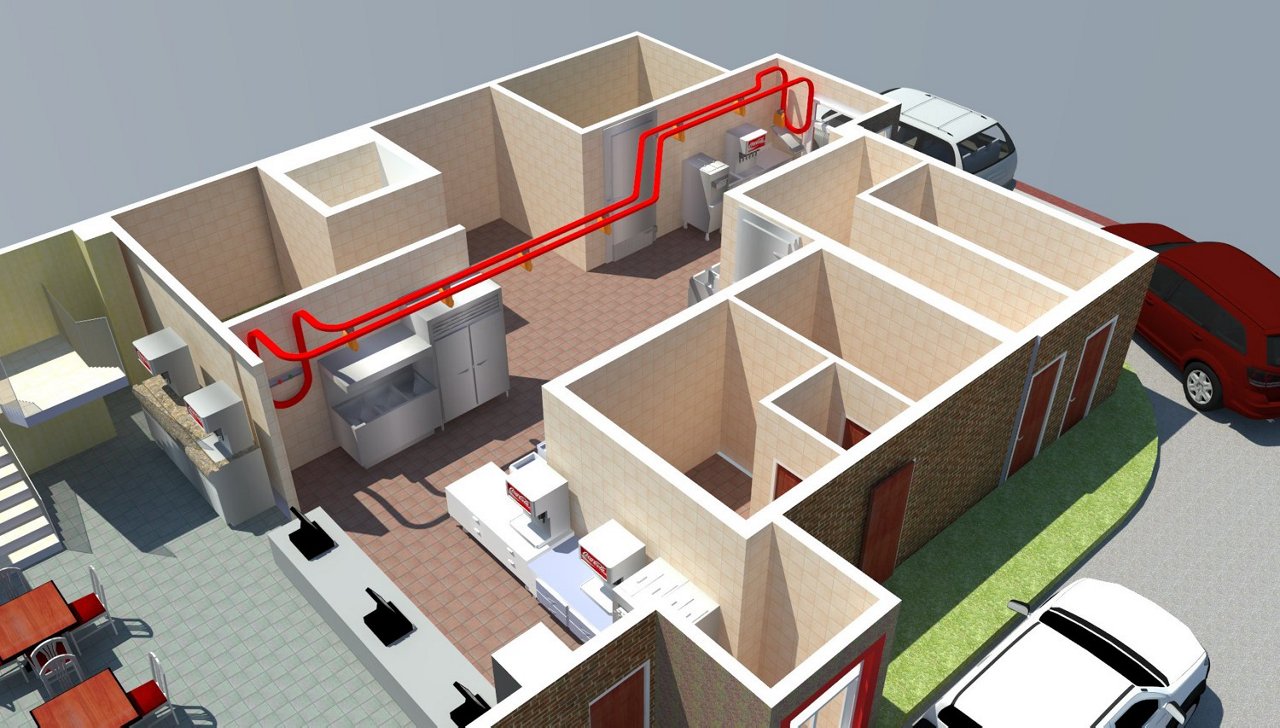

A versatile transporting system using “baskets” to carry prepared food from kitchen area to a remote customer service area, either on the same floor or on a different level. Modularized design makes it highly efficient in terms of configuration, manufacturing and installation.

See how the Bag & Clip Transporter works in a challenging layout

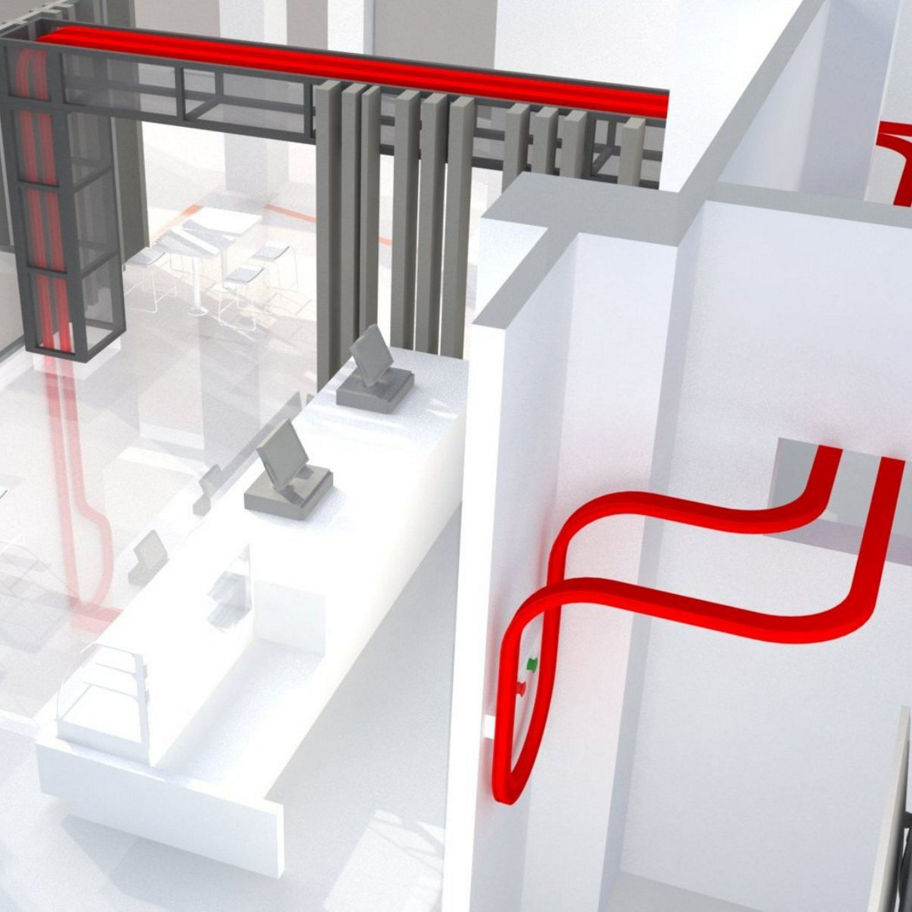

A customized transporting system using “clips” to best suit the unique project requirement. Food products are carried in bags from a loading point to a remote delivery point, either on the same floor or on a different level. Track system is typically suspended under the ceiling or enclosed above the ceiling.

Transporter Document Downloads

Connect with us

Innovations move us forward, and Franke is prepared to take you further. Send us your messages and questions on what solutions can be tailored to you.

Call Us

In EMEA region: +49 7761 5533 5700 In Americas region: +1 800 472 2954 In APAC region: +86 750 841 8466